NON DESTRUCTIVE TESTING

Our Non Destructive Testing operators have all recently been re-certified to Level 1. They are all proficient in Liquid Dye Penetrant, Magnuflux, Eddy Current and Ultra Sonic testing methods. Additionally we are also capable of leak testing under pressure using liquid or air.

INSPECTION & SORTING

Our diligent inspectors will sort 100% visually using white light or bore-scope for appearance, cosmetic imperfections or cleanliness. Additionally, all parts can be tested for functionality and/or measured to a range of dimensional tolerances with all results including manufacturing dates being recorded and sorted to customer specs.

Measuring Critical Tolerance

Visual Inspection

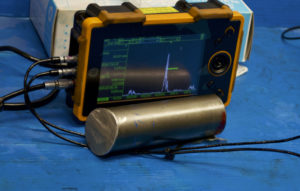

Ultra Sonic Testing

Ultrasonic testing uses the same principle as Sonar and fish finders. High frequency sound is introduced into the part and if a void or imperfection impedes or accelerates the sound reflection back to the sending unit, a visual display alerts the operator to the abnormal condition. This method is better suited to finding flaws much deeper than any surface method is capable of.

Ultrasonic testing uses the same principle as Sonar and fish finders. High frequency sound is introduced into the part and if a void or imperfection impedes or accelerates the sound reflection back to the sending unit, a visual display alerts the operator to the abnormal condition. This method is better suited to finding flaws much deeper than any surface method is capable of.

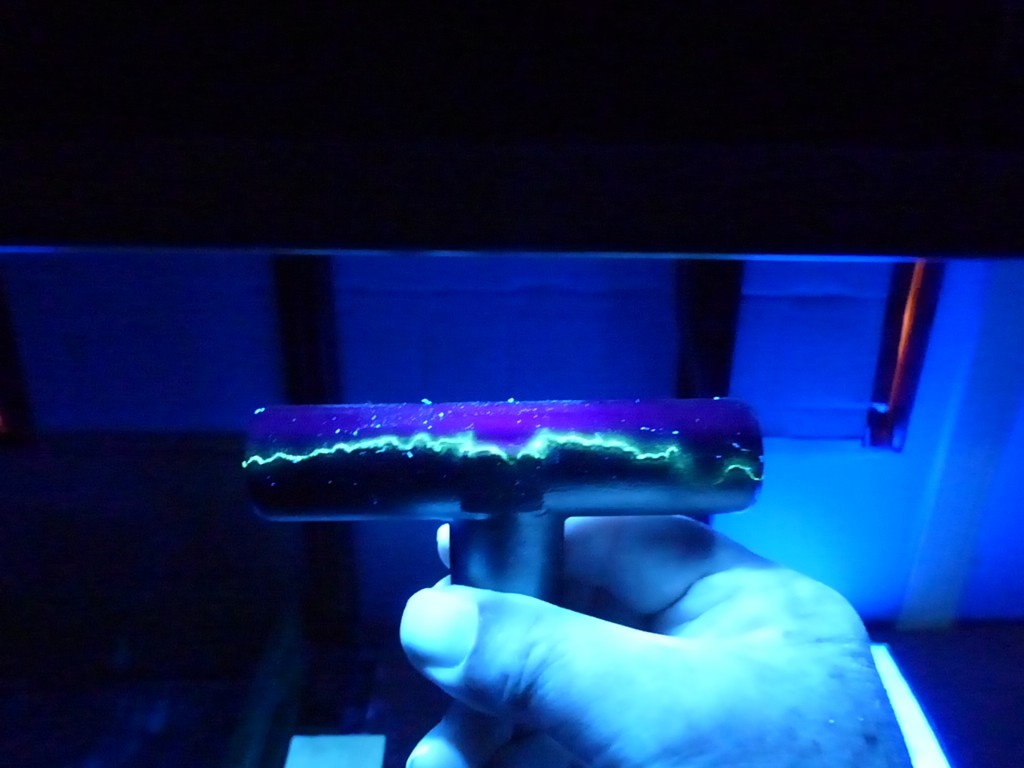

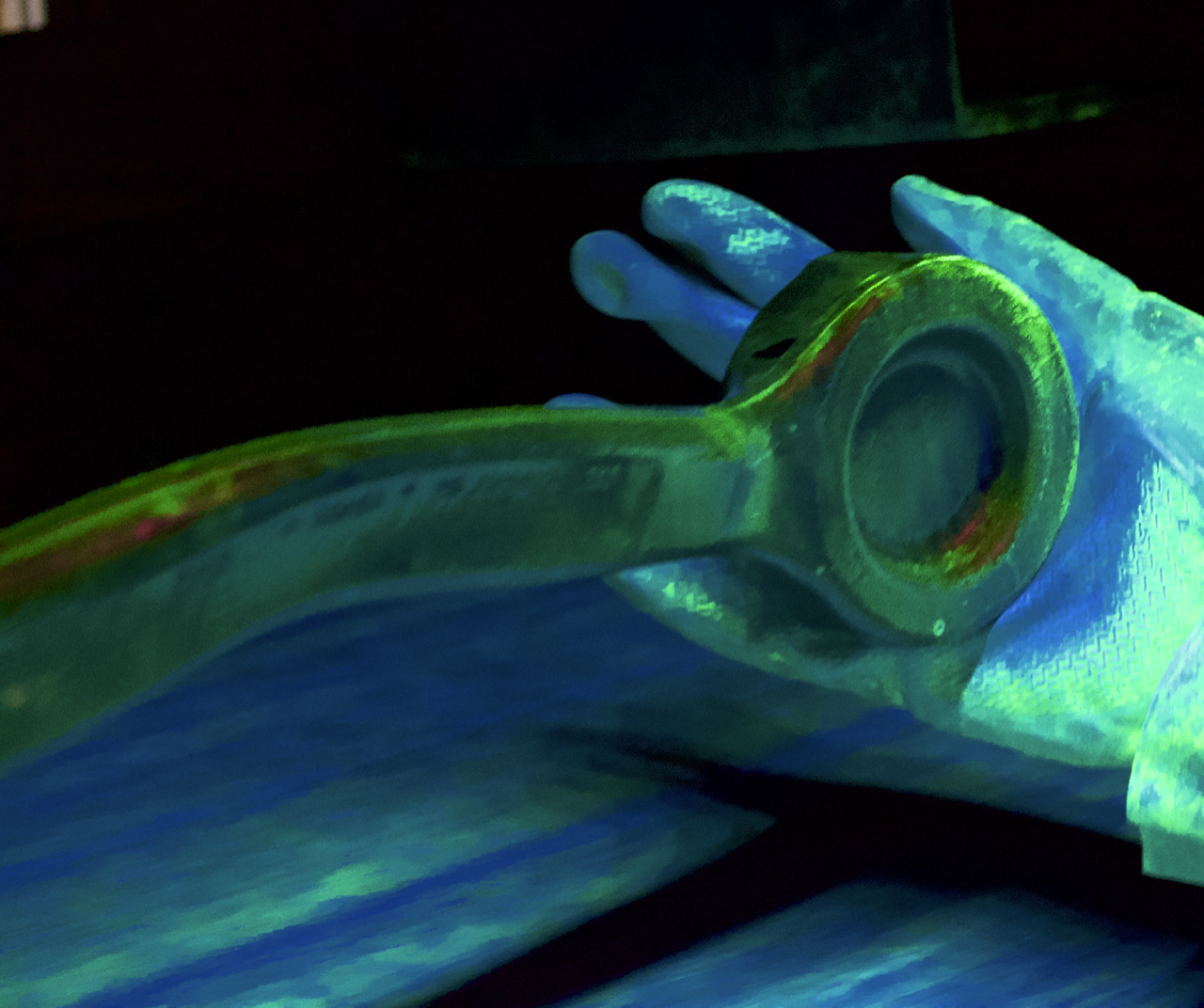

Liquid Penetrant Inspection (LPI)

The advantage that Tora liquid penetrant inspection (LPI) offers over an unaided visual inspection is that it makes defects easier to see for the inspector. There are basically two ways that a penetrant inspection process makes flaws more easily seen. First, LPI produces a flaw indication that is much larger and easier for the eye to detect than the flaw itself. Many flaws are so small or narrow that they are undetectable by the unaided eye. The second way that LPI improves the detectability of a flaw is that it produces a flaw indication with a high level of contrast between the indication and the background also helping to make the indication more easily seen. When a visible dye penetrant inspection is performed, the penetrant materials are formulated using a bright red dye that provides for a high level of contrast between the white developer. The developer serves as a high contrast background as well as a blotter to pull the trapped penetrant from the flaw. When a fluorescent penetrant inspection is performed, the penetrant materials are formulated to glow brightly and to give off light at a wavelength that the eye is most sensitive to under dim lighting conditions.

Before

After

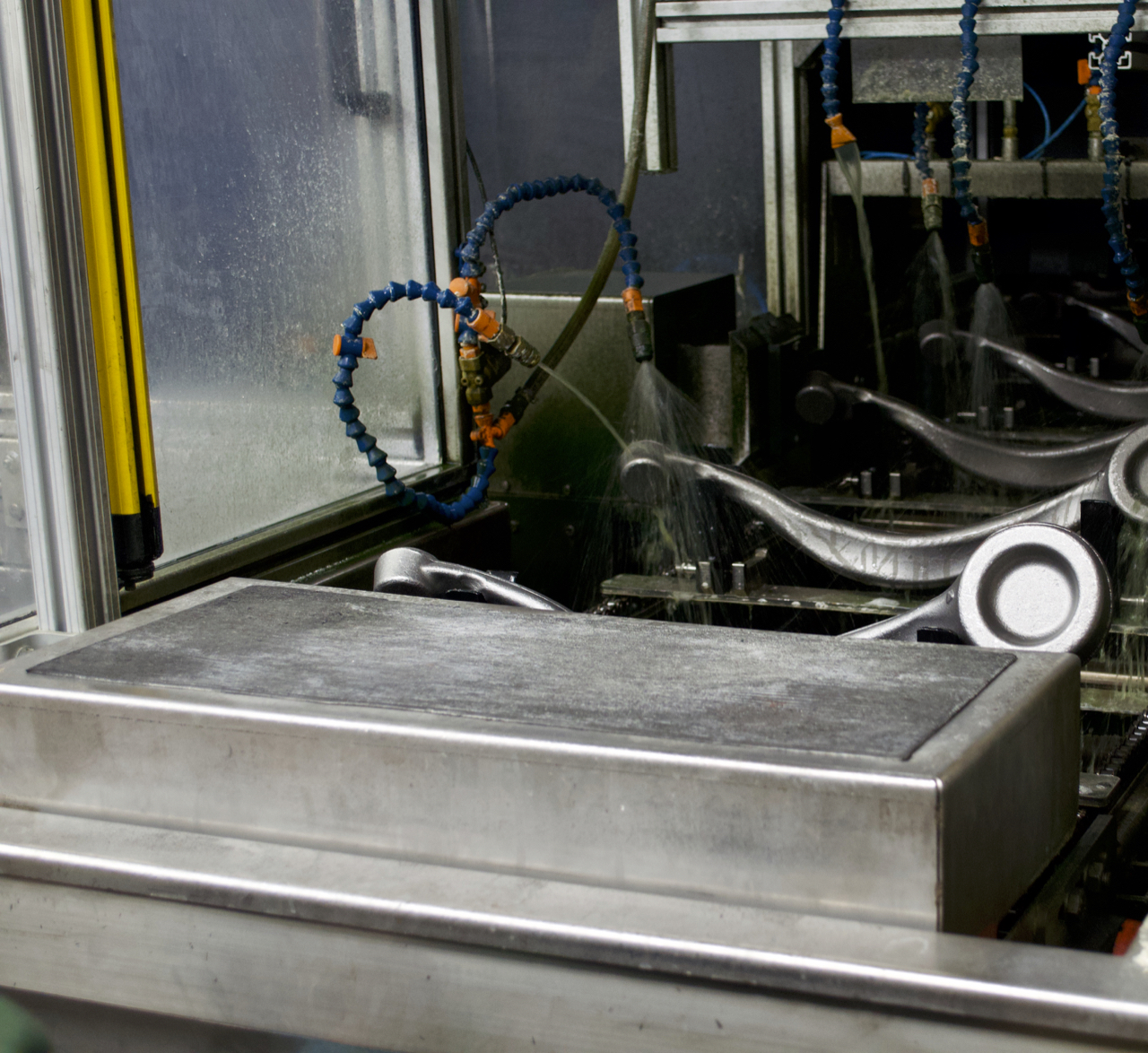

Magnaflux

White Light Inspection

Solution Application

UV Light Inspection